-

-

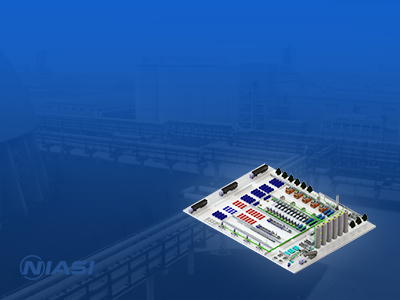

- Central Conveying System NIASI is capable of providing complete central conveying system tailored to your plastics processing plant, with solution containing raw material storing, material drying, intralogistic conveying, smart control of production management, data collection and order planning.

-

-

-

- Industrial Chiller Industrial chiller provides molds with stable cooling to shorten the production cycle, also applied along with cooling equipment to control the work temperature, as well as other industrial sectors where efficient cooling is critical.

-

-

-

- Temperature Control Units (TCU) NIASI mold temperature controller uses water or oil as its heat transfer medium. The medium is pressurized by pump and heated by electrical heat tube, and then conveyed to molds to accomplish mold heating and maintain a constant temperature. Optimized design enables water to be heated up to 120℃ and oil to be heated up to 200℃.

-

-

-

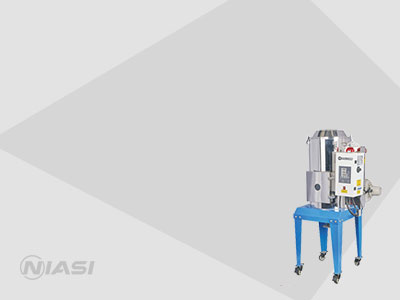

- Dehumidifier Dryer NIASI is capable of providing complete central conveying system tailored to your plastics processing plant, with solution containing raw material storing, material drying, intralogistic conveying, smart control of production management, data collection and order planning.

-

-

-

- Mixing and Dosing System (Coloring) NIASI provides gravimetric dosing and blending systems that are specially designed to meet customers’ requirements of stable production, high efficiency and lower scrap volumes.

-

-

-

-

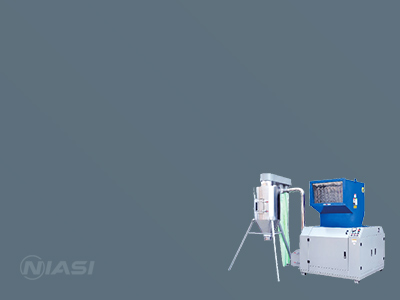

Size Reduction Machine (Shredder and Granulator)

This combined shredder and granulator is designed with a soundproof housing, primarily used for shredding and recycling of rejected products in plastic processing.

Built-in soundproof enclosure, low noise level

-

No.3 Gaobao Road, Changping Town, Dongguan City, Guangdong Province

No.3 Gaobao Road, Changping Town, Dongguan City, Guangdong Province Miss HE

Miss HE