We provide a suitable solution in the manufacturing of every plastic processing industries., including injection molding, extrusion, blowing, compounding and recycling, etc.

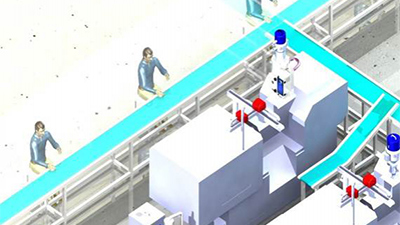

NIASI is capable of providing solution suited to your plastic processing applications including injection molding, extrusion, blow molding, compounding and recycling, etc. Our portfolio includes conveying system, storing system, dosing system, weighing system and recycling system. Our customized solutions are provided satisfying your specific needs in terms of cost control, quality and safety.

Along with our monitoring software, it is possible to achieve remote monitoring, networked communication between all systems and automatic collecting of production data, enabling us to reach Industry 4.0 level and to assist our customer creating more benefits.

We do not consider ourselves as conventional supplier to provide equipment and service, but far more as a designer and planner of automation, rationalization and environmental protection. We pride ourselves in our experience and expertise across all processes in plastic processing industry.节。

-

-

-

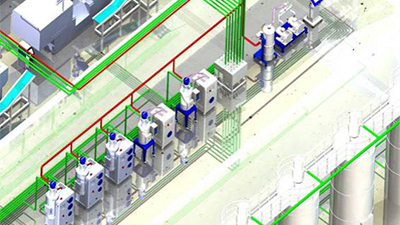

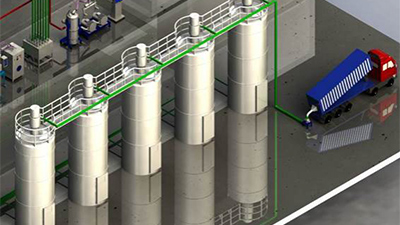

Central conveying system for plastic processing

- Custom manufactured adapting to your application of plastic processing

- Material conveying is controlled and managed by software and control system, eliminating the worry of systemless production

- Continuous operation

- Modular design, in compliance with the requirements of Industry 4.0 technology

- Short cost recovery period

-

-

-

-

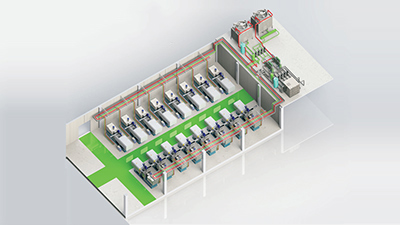

Constant-temperature and constant-pressure water supply system

- Automatically adjust water pressure, water flow and water temperature, efficiently saving consumption of water and power

- Water supply with constant pressure can save power by 20-30%, smooth running and low failure rate

- Stable water pressure and accelerated water flow provide a better cooling efficiency for injection molding machine

- Equipped with protection devices and pipe anti-freeze unit

-

-

-

-

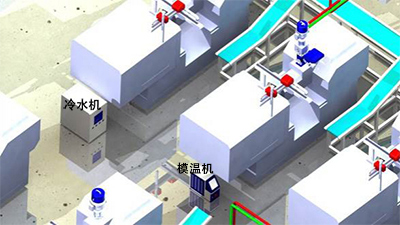

Mold cooling and mold temperature controlling system

- We can provide you with mold cooling and temperature control system suited to any engineering plastic whether it is PC, PP, PA or others

- Core parts are made of stainless steel, ensuring high quality

- Temperature control unit adopts water or oil as heat transfer medium to heat up the mold while maintaining a constant temperature

-

-

-

-

Dehumidifying and drying system

- Dehumidifying dryer is suitable for drying of hygroscopic engineering plastics, strict controlling of water content in raw materials is critical in manufacturing high quality plastic products

- Japanese NICHIAS dehumidifier is adopted to ensure better dehumidifying effect with stable performance

- High automation, greatly reducing labor force

- PID temperature control

-

-

-

-

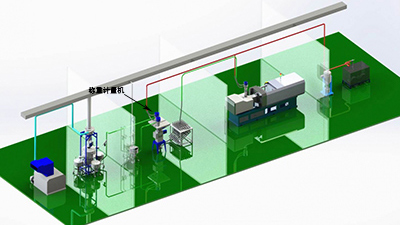

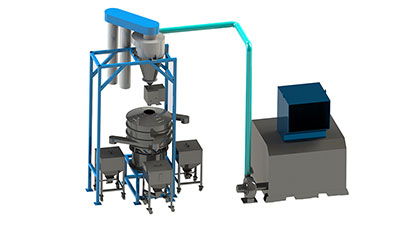

Gravimetric dosing system

- Can implement accurate weighing and even mixing of 2 up to 6 kinds of materials, containing virgin materials, regrinds, masterbatch and various additives

- Recipe percentages (proportion of various materials) can be set, easy to operate

- Continuous operation precisely and stably

- Can weighing and dosing of next batch of materials while the materials being mixed

- Automatic compensation and calibration function

-

-

-

-

Size reduction machine (shredder and granulator)

- Compact design with built-in soundproof enclosure, double walled stainless steel feed hopper enables noise level lowered by 20dB(A)

- High quality wear resistant cutting tools are made of material D2 or SKD-II

- From our solution, shredded materials will be conveyed through metal separator to eliminate metals from materials. The metal separator can also be used for detection of metals from incoming raw materials

-

No.3 Gaobao Road, Changping Town, Dongguan City, Guangdong Province

No.3 Gaobao Road, Changping Town, Dongguan City, Guangdong Province Miss HE

Miss HE