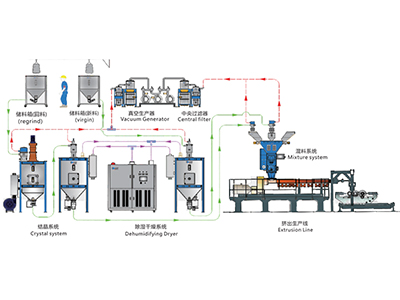

PET crystallizer is used to re-crystallize PET amorphous materials before drying, thus preventing the formation of clumps. After re-crystallized, PET materials will be conveyed to material storage bin or directly to drying hopper. NIASI offers dehumidifying and drying system for PET material processing with a throughput up to 8000kg/h, the final water content of dehumidified materials reaches down to 0.004% and below.

Specifications

| Model | NCR-160L | NCR-450L | NCR-900L | NCR-1600L | NCR-2500L |

| Hopper capacity (L) | 160 | 450 | 900 | 1600 | 2500 |

| Mixing motor power (KW) | 0.25 | 0.55 | 1.5 | 1.5 | 4 |

| Blower power (KW) | 0.55 | 2.2 | 3 | 7.5 | 15 |

| Heater power (KW) | 12 | 24 | 48 | 96 | 128 |

| Max. processing capacity (Kg/hr) | 50 | 150 | 300 | 500 | 750 |

| H(mm) | 2380 | 3850 | 4450 | 5350 | 5670 |

| H1(mm) | 280 | 720 | 1040 | 860 | 1270 |

| H2(mm) | 380 | 1060 | 1185 | 1260 | 1270 |

| W(mm) | 1040 | 2370 | 2890 | 3570 | 4050 |

| W1(mm) | 1140 | 1440 | 1930 | 2190 | 2350 |

| W2(mm) | - | 800 | 800 | 800 | 800 |

| ΦA(inch) | 3 | 5 | 6 | 8 | 8 |

| ΦB(inch) | 4 | 4 | 5 | 5 | 5 |

| Net weight (Kg) | 235 | 500 | 865 | 2290 | 2790 |

Photo Gallery

No.3 Gaobao Road, Changping Town, Dongguan City, Guangdong Province

No.3 Gaobao Road, Changping Town, Dongguan City, Guangdong Province Miss HE

Miss HE